roughing end mill depth of cut

KenCut HT Full Ceramic End Mill for Roughing of Nickel Based Alloys. Inches per revolution ipr feed rate of.

Imco Carbide 33181 Carbide Square End Mill M104 1 2 In Shank Diameter 2 1 2 In Oal 5 8 In Cut Depth 1 2 In Tool Diameter Groves Industrial

Learn what they are when each is the best technique.

. RF 100 Speed End Mills. Thats something you need to figure out empirically. Due to variable spacing of flutes combined with the NR roughing profile vibrations.

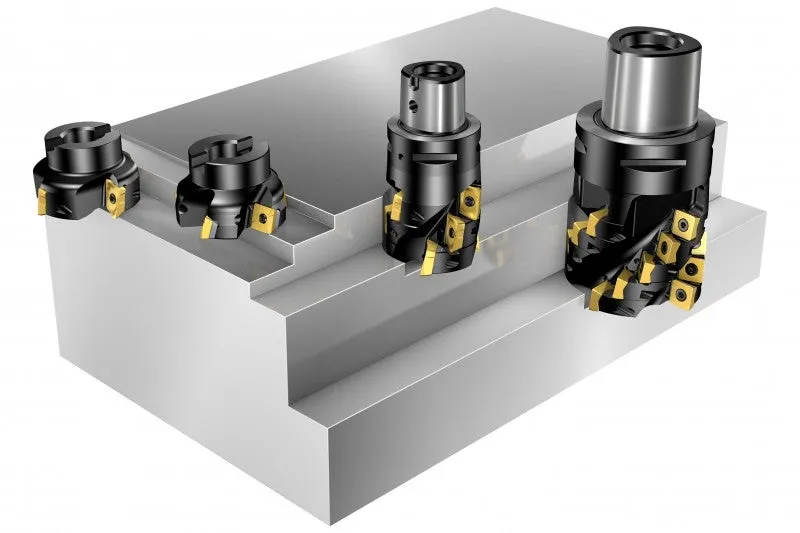

Multi-Cut end mills are specifically designed for high-performance roughing operations. Round inserts and concepts with radius are milling cutters used for roughing and semi-roughing while ball nose end mills are milling cutters used for finishing and super-finishing. Widia hanita 5329388 series eccentric rougher 6 flute inch roughing finishing end mill 762 mm max depth of cut 3175 mm dia shank.

Standard depths of cuts for roughing end mills can be set at a larger value than ordinary type end mills. Answer 1 of 5. P H P M R R K C 400.

They may seem similar to many people Skip to content 86-18505123093 86. A ball end mill is constructed of a round cutting. Carbide Square End Mills.

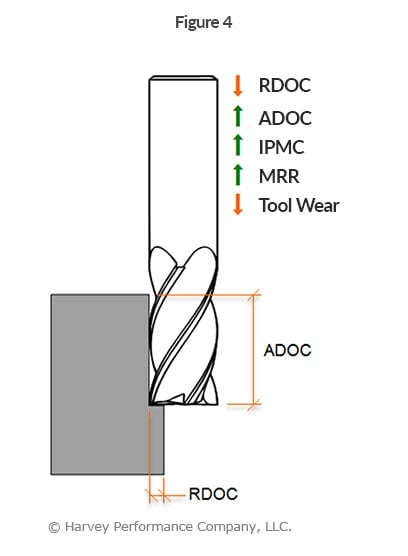

KenCut RR Solid Carbide End Mill for Roughing of Steels Stainless Steel Cast Iron. This is because the cutting resistance is reduced because the chips are broken into short. The power consumption in a milling process is calculated by the Metal Removal Rate MRR times the Specific Cutting Force KC.

Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard. Thats approximately the maximum cutting depth for an end mill if you want. Features and benefits Full ceramic end mills offer highest productivity and tool life in roughing nickel-based high.

Out of the most common milling tools there are roughing end mill and finish end mill. Clearing Welded on Aluminum from End Mills Drill Bits and Inserts. RF 100 90 End.

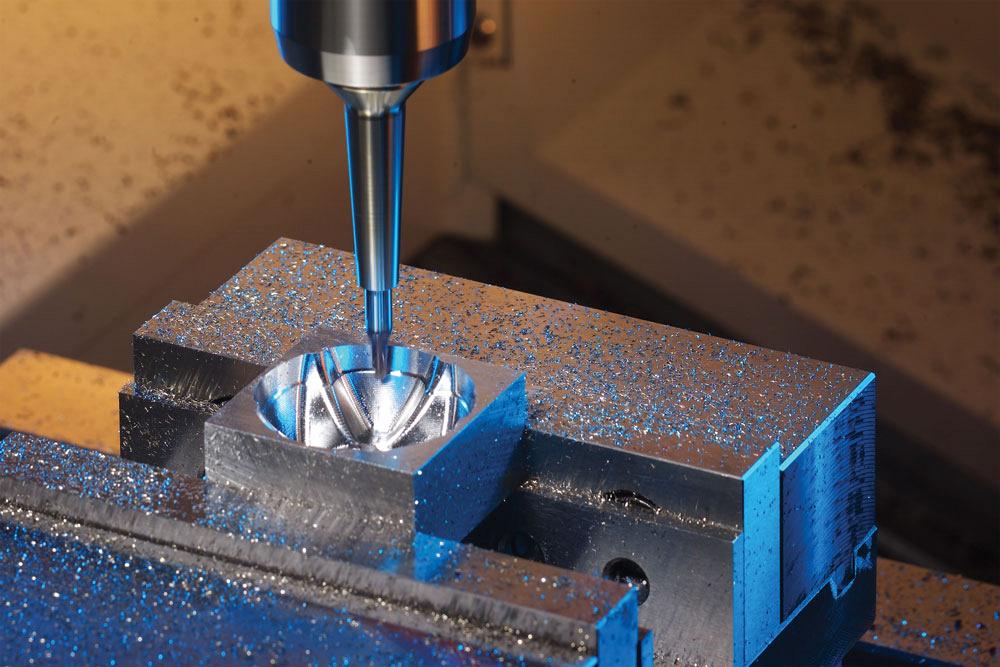

There is no recommended cutting depth. Climb Milling versus Conventional Milling. Up to 16 cash back Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

CLICK to browse 16 DEPTH OF CUT MM ROUGHING GENERAL PURPOSE END MILLS made by world class cutting tool manufacturer Guhring.

Preparing For Hard Metal Milling

Kor 5 High Velocity Aluminum Roughing Youtube

400 Sfm In Titanium With Helical S Hvti End Mill Youtube

Endmill Selection Guide Redline Tools Redline Tools

High Efficiency Roughing Endmill For Difficult To Cut Material 4 5 6rfh Youtube

Tutorials Processing Tutorials Milling Roughing And Finishing With Mill

High Efficiency Vs High Feed Milling Which Is More Productive Modern Machine Shop

6 Essential End Mills For Your Cnc Machine Make

Dormer C40014 0 Shank Roughing End Mill Bright Coating Cobalt High Speed Steel 14 Mm Head Diameter 26 Mm Flute Length Amazon Com Industrial Scientific

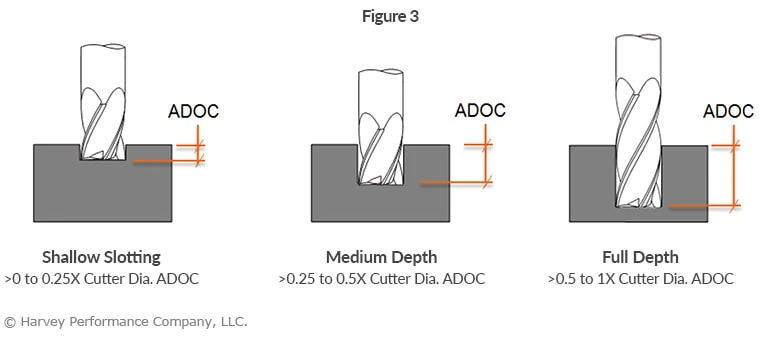

Diving Into The Depth Of Cut In The Loupe Machinist Blog

Morse Cutting Tools Milling Solid Square Corner Radius End Mills 3 4 3 4 1 5 8 3 3 4 4 Flute Single End Hssco Roughing Finishing Center Cutting End Mill Uncoated Series List 4640 Mt2945121

Diving Into The Depth Of Cut In The Loupe Machinist Blog

Guide How To Select The Best Cnc End Mill

Speed Feed Recs Melin Tool Company

Basic End Mills Technical Information Msc Industrial Supply Co

Shell End Milling Cutter Turbo 12 Seco Tools Insert Roughing Semi Finishing